Təsvir

Enjeksiyon molding is a istehsal process for producing parts by injecting molten material into a mold. Plastic Enjeksiyon Molding is one of the most frequently used istehsal

processes for creating plastic parts. Thanks to its high-precision,

repeatability, and cost efficiency at scale, plastic injection molding is used for

a variety of products and parts from the smallest insert up to large automotive

& aerospace parts.

Plastik enjeksiyon kalıplama prosesi bir enjeksiyon kalıplama maşını, xam plastik material və işlənmiş bir kalıp tələb edir. Xam plastik material əvvəlcə enjeksiyon bölməsində əridilir və sonra qəlibə enjekte edilir, burada soyudulur və son plastik hissəyə bərkimiş olur.

The key steps in the injection molding process include:

-Clamping

Kalıbın iki tərəfi bağlanır və sıxılır.

-Enjeksiyon

Material maşın içərisinə verilir və qəlibə doğru itilir. Bu baş verərkən, istilik və təzyiq nəticəsində material əridilib. Daha sonra plastik qəlibə enjekte edilir, bu prosesə "Şüşə" deyilir.

-Soyutma

The plastic in

the mold cools and solidifies into the shape of the part.

-Ejeksiyon

Parçalardan sonra qəlibdən atılır.

Auwell offers 2 business models to meet the needs of the client for

plastic injection molding projects. Namely supply tooling only models or, final

products models.

-Tooling Only Models

For this business model,

Auwell offers the tooling design based on the product design and machine data

for client confirmation, the details include tooling structure, lifetime,

tooling material, hardness, etc. Clients may provide completed tooling designs

for production. For this tooling only option, for standard parts, we will use the

most common with globally recognized one for easy maintenance. In general, this

option is preferred for large size and high-volume products, Plastic

Enjeksiyon Tooling Avtomobil is a typical catalogue for this business

model.

-Son Məhsul Modelləri

For this business model, Auwell is responsible for the plastic injection molding parts, and to meet the client’s specifications. The type of injection machine and tooling structure/design used is decided by our team. For this business model, once the client pays the tooling cost, Auwell will be responsible for tooling maintenance and replacement for the entire product lifetime. This model is preferred for small sizes and precise plastic injection molding parts. Please refer to “Plastic Enjeksiyon PartsDaha ətraflı məlumat üçün bölmə.

Another key difference of the two-business model is, for “Tooling Only

Model”, the mold cost is considerable higher than “Final Products Model” as for

“Final Products Model”, Auwell does not make any margin from the tooling

development. For “Final Products Model”, if the clients want to take the mold

or, shift to another supplier, it is not guaranteed that the mold works

properly at another machine at another manufacture, and, a certain proportion

of mold development cost will be charged before mold transferring.

Plastik enjeksiyondan başqa, aşağıdakı xidmətləri də təqdim edirik:

-Sürətli 3D çap prototipləri

-Overmolding

-Kalıp əlavə edin

-Thermoforming

-Kauçuk və Silikon Kalıplama

Technical Specifications

-Material

Following plastic

material available for our plastic injection molding services:

Ø PA 6/6 | Polyamide 6/6, Nylon 6/6

Ø PARA | Poliaril Amid

Ø PBT | Polybutylene Terephthalate, Valox

Ø PBT-PET | Polybutylene Tereftalat-Polietilen Tereftalat

Ø PC | Polikarbonat

Ø PC-ABS | Polycarbonate-Acrylonitrile Butadiene Styrene

Ø PC-PBT | Polycarbonate-Polybutylene Terephthalate, Xenoy

Ø PC-PET | Polycarbonate-Polyethylene Terephthalate

Ø PCT | Polisikloheksilenedimetilen Tereftalat

Ø PE | Polietilen

Ø PE-PP | Polietilen-Polipropilen

Ø PE-PS | Polietilen-Polistirol

Ø PEBA | Polieter Block Amide

Ø PEEK | Polyether Ether Ketone

Ø PEI | Polieterimid, Ultem

Ø PES | Polieter Sülfon

Ø PET | Polyethylene Terephthalate, Rynite

Ø PLA | Polylactic Acid

Ø PMMA | Polimetil metakrilat, akril

Ø POM | Asetal Polioksimetilen, Delrin

Ø PP | Polypropylene

Ø PPA | Poliftalamid

Ø PPS | Polifenilen sulfid, Ryton

Ø PS | Polistirol

Ø PS-PPE | Polystyrene-Polyphenyl Ethers, Noryl

Ø PSU | Polisülfon, Udel

Ø PVC | Polivinil xlorid (sahil D)

Ø PVDF | Poliviniliden florid

Ø SAN | Styrene Acrylonitrile

Ø TPO | Termoplastik Poliolefin

Ø TPU | Thermoplastic Polyurethane (Shore D)

Ø Xüsusi qaynaqlı qatran

-Moldbase

LKM, HASCO, 1.1730, S50C, S55C, 1050, 1055

-Aktiv elementlər

Ø P20, 1.2311, 1.2312, 1.2738, 1.2343, 1.2344, H11, H13, 420

Ø ASSAB: 718, 718S, 718H, S316/S316H/S316 SUP/S316H SUP, POLMAX/168

Ø SAARSTAHL: GS738, GS2311, GS2312, GS638, GS688, GS2316

Ø DAIDO: NAK80, NAK55, PX88, PX4, PX5, S-Star (A)

Ø BOHLER: M201, M202, M238, M300 ESR, M310 ESR, M310H ESR

-Hotrunner

YUDO, INCOE

-Kalıp səthi

Fotoşəkil aşındırma, aşınma quruluşu, zərbə partlayıcısı, xətt cilalama, yüksək cilalama, güzgüPolləmə.

-Machines: 100-3,000 ton

closing force

Üstünlükləri

-Rich Experience

More than 20 years of

experience in plastic injection molding tooling development and part production,

especially to the European and North American markets, with solid understanding

of the material, technical and quality standards worldwide.

-Sürətli dönüş

Generally, we provide a

quotation within 3 working days. Combining the latest istehsal

technologies and facilities, Auwell is able to provide fast prototypes in 3

working days, for simple and small size tooling, we are able to deliver first

sample in 4 weeks.

-Hərtərəfli həll təminatçısı

Auwell provides

comprehensive services for plastic injection molding projects starting from

designing, through prototyping, tooling/fixture development, sampling, mass

production, and to logistic and post-sale support.

-Rigid QC Policies

The most rigorous quality

policy starts from material control, and is followed through to final

pre-shipment inspection. Material certificates include the mill certificate,

3rd party chemical components, and mechanical property reports, as well as RoHS

and REACH reports upon request. We structure our processes, creating Flow Charts

and Control Plans before production, making sure all QC processes are in accordance

with ISO9001-2015 requirements and drawing specifications.

-Flexible Payment Term

Alət üçün ümumi ödəmə müddəti 50% -40% -10%, yəni% 50 depozit, ilk nümunə pulsuz olduqdan 40% və müştəri alət alandan və ya ilk məhsul məhsulunu aldıqdan 2 həftə sonra 10% deməkdir. Formas istehsalı, çevik ödəmə şərtləri təqdim edirik, məqbul kredit şərtləri veriləcək, müştəri yalnız aldığı məhsuldan məmnun olduqda ödəyir. Uzunmüddətli layihələr üçün sürətli çatdırılma tələblərinə cavab verən inventar xidmətləri təklif edirik.

Proqramlar

-Plastik enjeksiyon

məhsullar demək olar ki, bütün sənaye sahələrində geniş yayılmışdır

o cümlədən:

-Aerospace and defense

-Avtomobil

-Agriculture Machinery

-Enerji

-Electronics

-Construction

-Nəqliyyat

-Industrial

-Consumer Products

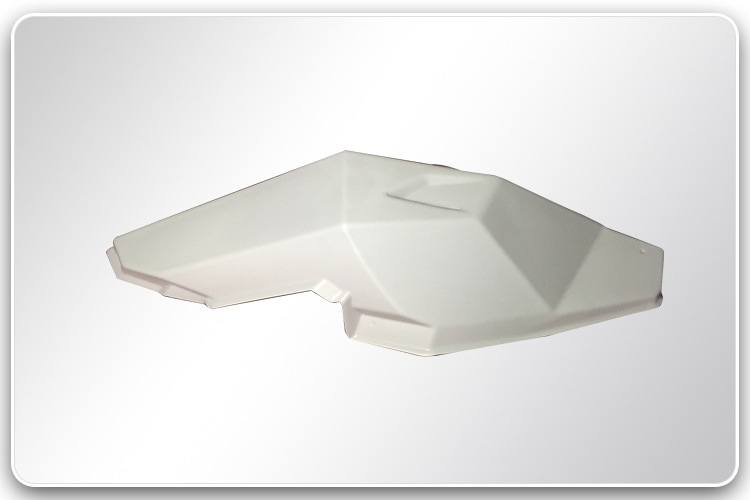

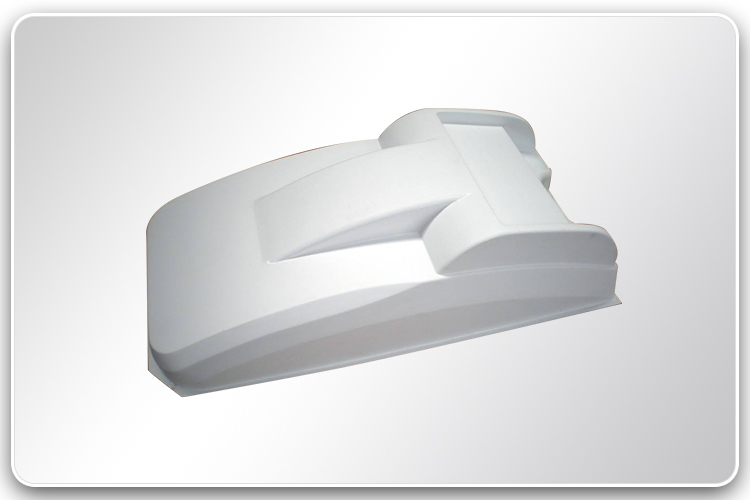

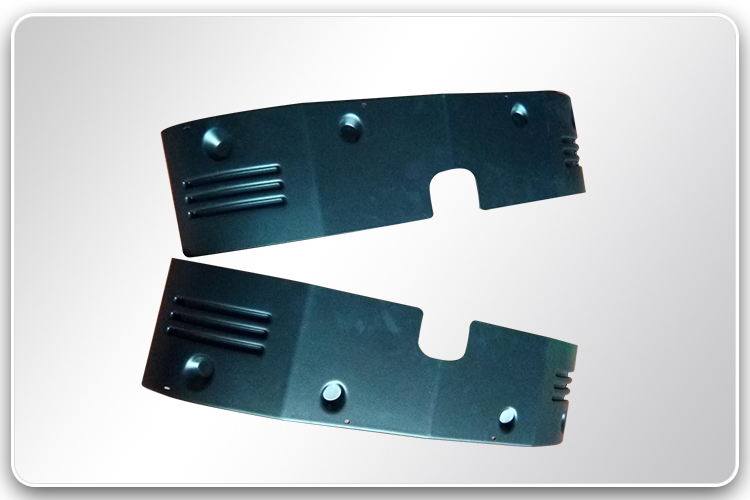

The following catalogues of plastic injection molding products

are the ones which Auwell has produced and supplied to our distinguished

worldwide clients. Please click the relevant pictures for details. Please be

advised, most of the products are for demonstration purpose only.

Plastic Enjeksiyon Mold for Avtomobil Parts

Plastic Enjeksiyon Mold for Avtomobil Parts

Plastic Enjeksiyon Parts

Plastic Enjeksiyon Parts

Plastic Enjeksiyon Overmolding

Plastic Enjeksiyon Overmolding

Plastic Thermoforming Parts

Plastic Thermoforming Parts

Kauçuk və Silikon Kalıplama

Kauçuk və Silikon Kalıplama

English

English  Español

Español  Português

Português  русский

русский  Français

Français  日本語

日本語  Deutsch

Deutsch  tiếng Việt

tiếng Việt  Italiano

Italiano  Nederlands

Nederlands  ภาษาไทย

ภาษาไทย  Polski

Polski  한국어

한국어  Svenska

Svenska  magyar

magyar  Malay

Malay  বাংলা ভাষার

বাংলা ভাষার  Dansk

Dansk  Suomi

Suomi  हिन्दी

हिन्दी  Pilipino

Pilipino  Türkçe

Türkçe  Gaeilge

Gaeilge  العربية

العربية  Indonesia

Indonesia  Norsk

Norsk  تمل

تمل  český

český  ελληνικά

ελληνικά  український

український  Javanese

Javanese  فارسی

فارسی  தமிழ்

தமிழ்  తెలుగు

తెలుగు  नेपाली

नेपाली  Burmese

Burmese  български

български  ລາວ

ລາວ  Latine

Latine  Қазақша

Қазақша  Euskal

Euskal  Azərbaycan

Azərbaycan  Slovenský jazyk

Slovenský jazyk  Македонски

Македонски  Lietuvos

Lietuvos  Eesti Keel

Eesti Keel  Română

Română  Slovenski

Slovenski  मराठी

मराठी  Srpski језик

Srpski језик